About the product

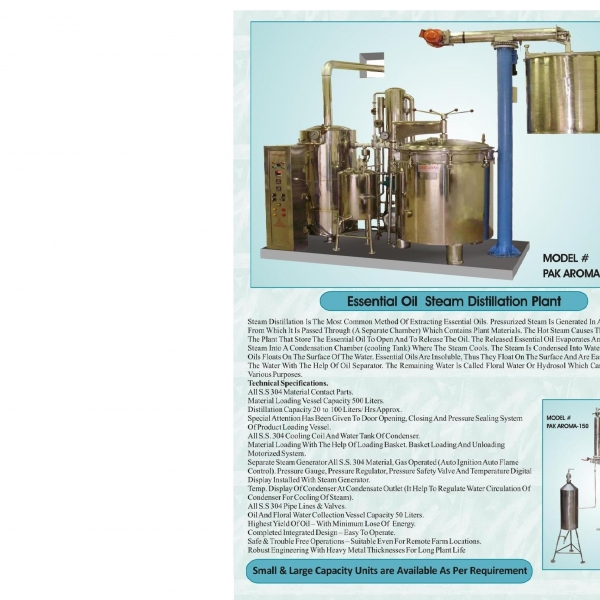

Steam Distillation Plant for Essential Oil Extraction.

Steam distillation is the most common method of extracting essential oils. Pressurized steam is generated in a separate chamber from which it is passed through (a separate chamber) which contains plant materials. The hot steam causes the walls of cells in the plant that store the essential oil to open and to release the oil. The released essential oil evaporates and is carried by the steam into a condensation chamber (cooling tank) where the steam cools. The steam is condensed into water and the essential oils floats on the surface of the water. Essential oils are insoluble, thus they float on the surface and are easily separated from the water with the help of oil separator. The remaining water is called floral water or hydrosol which can also be used for various purposes.

Technical specifications.

All S.S 304 Material contact parts.

Material loading vessel capacity 100/1000 Liters, as per requirement.

Distillation capacity 25/200 liters/ Hrs approx.

Special attention has been given to door opening, closing and pressure sealing system

of product loading vessel.

All S.S. 304 Cooling Coil and water tank of condenser.

Material loading with the help of loading basket. Basket Loading and unloading motorized system.

Separate steam generator MS or all S.S. 304 material, Gas Fired, Wood Fired, Cool Fired

, Electrically Operated, semiautomatic or full automatic (Auto ignition auto flame control).Pressure gauge, pressure regulator, pressure safety valve and temperature digital display installed with steam generator, all model are available as per requirement.

Temp. display of condenser at condensate outlet (it help to regulate water circulation of condenser for cooling of steam).

All S.S 304 pipe lines & Valves.

Oil and floral water collection vessel capacity 50/100 Liters.

www.pamicotechnologies.com

Steam distillation is the most common method of extracting essential oils. Pressurized steam is generated in a separate chamber from which it is passed through (a separate chamber) which contains plant materials. The hot steam causes the walls of cells in the plant that store the essential oil to open and to release the oil. The released essential oil evaporates and is carried by the steam into a condensation chamber (cooling tank) where the steam cools. The steam is condensed into water and the essential oils floats on the surface of the water. Essential oils are insoluble, thus they float on the surface and are easily separated from the water with the help of oil separator. The remaining water is called floral water or hydrosol which can also be used for various purposes.

Technical specifications.

All S.S 304 Material contact parts.

Material loading vessel capacity 100/1000 Liters, as per requirement.

Distillation capacity 25/200 liters/ Hrs approx.

Special attention has been given to door opening, closing and pressure sealing system

of product loading vessel.

All S.S. 304 Cooling Coil and water tank of condenser.

Material loading with the help of loading basket. Basket Loading and unloading motorized system.

Separate steam generator MS or all S.S. 304 material, Gas Fired, Wood Fired, Cool Fired

, Electrically Operated, semiautomatic or full automatic (Auto ignition auto flame control).Pressure gauge, pressure regulator, pressure safety valve and temperature digital display installed with steam generator, all model are available as per requirement.

Temp. display of condenser at condensate outlet (it help to regulate water circulation of condenser for cooling of steam).

All S.S 304 pipe lines & Valves.

Oil and floral water collection vessel capacity 50/100 Liters.

www.pamicotechnologies.com

Price

150,000-00 to 1500,000-00

Contact with supplier

Company